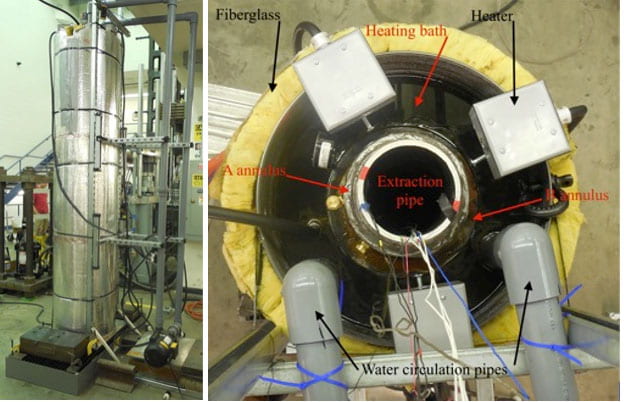

Due to difficulty in proper placement and change in downhole environment, well cementing may fail to achieve zonal isolation, resulting in an increase in annular casing pressure, causing concerns of well integrity and safety. Vibration control can be a useful tool to prevent failures in the cement layers surrounding oil well tubing. Installing fiber optic accelerometers on the internal wall of the production tube may allow detecting any change in the tube’s external pressure and temperature, which is reflected in the tube’s vibration characteristics (e.g. natural frequency shift, damping, etc.). A timely detection could allow suspending the oil and gas extraction before unwanted spilling creates huge losses both from economic and environmental standpoints. Goal of the study was to experimentally investigate the dynamic behavior of the oil drilling tubing when changes in its external temperature and pressure occur.

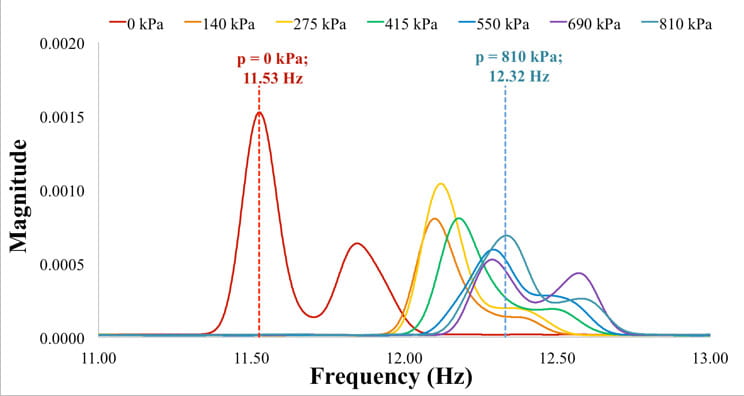

The study was based on a scaled model of an oil well production pipeline with several accelerometers installed on the internal wall of the extraction pipe to monitor vibration characteristics changes. Heating elements and a pump were used for changing the temperature and the pressure of the system and of the oil contained inside the extraction pipe, while a shaker was used to excite the tube as nine different temperature–pressure scenarios were simulated. The experiments demonstrated that change in temperature and/or pressure could be detected from the acceleration time histories measured and from analyses performed in the frequency domain.