Prof. Hansen teaches undergraduate courses, graduate courses, extracurricular learning opportunities, and engages in innovative engineering instruction.

Prof. Hansen teaches materials-oriented undergraduate courses, including Materials Science for Engineers, Strength of Materials, and Capstone Design.

Prof. Hansen teaches composite materials-oriented courses at the graduate level, including Processing of Composites and Experimental Characterization of Composites.

Prof. Hansen teaches outside of the classroom, including summer camps and 3D printing certifications.

Prof. Hansen has a history of engaging in innovative engineering instruction, including Service-Learning, national competitions, and Wikipedia instruction.

Undergraduate Courses

This course introduces the fundamentals of materials science to students majoring in mechanical Engineering. Materials properties (mechanical, thermal, durability, etc.) and their characterization are emphasized through lectures, labs, and projects. The course introduces students to long-form report writing, slide presentations, and team communication on projects.

Novel instructional techniques include service-learning and wikipedia projects.

This course introduces the fundamentals of deformable bodies. Stress and deformation of components subjects to uniaxial loading, thermal strain, torsion, bending, and combined loading are analyzed. Both statically determinate and indeterminate cases are considered. The course is lecture based, supplemented with online pre-lectures.

Novel instructional techniques include service-learning.

This design-focused course is the culmination of an undergraduate's mechanical engineering degree. Students apply design principles to identify an engineering problem, translate that problem into quantitative and qualitative engineering constraints and objectives, and then iteratively create a solution that meets the design needs. Most teams translate the design into an actual physical build.

Novel instructional techniques include service-learning and national team competitions.

See a class you wish to take? Visit the site for upcoming course schedules.

Graduate Courses

The goal of this course is to provide an overview of the both the scientific and practical aspects of processing composites. An emphasis is placed on polymer matrix fiber-reinforced composites, though short fiber-reinforced composites and metal- and ceramic-matrix composites are also discussed.

In addition to in-class lectures, students are invited to equipment and process demonstrations both on-campus (Advanced Composite Materials & Textiles Research Laboratory for hand lay-up, Plastics Engineering department for thermoforming) and off-campus (boron fiber CVD manufacturing at Specialty Materials Inc. and pultrusion and fiber winding at Plasan Composites)..

This course aims to introduce students to a broad range of characterization techniques for composite material properties and to interpret the results to determine performance. Properties range from constituent testing of matrix and reinforcement materials and characterization of microstructure to the macroscale testing of mechanical properties according to ASTM standards.

Lectures are complemented with hands-on characterization and examples that use real-world data collected in our research labs.

The goal of this course is to equip students with orthotropic stress-strain relations and failure criteria to analyze a broad range of composite materials. Students calculate the stress-strain response and failure of a laminated composite material under in-plane loading and/or bending using classical laminated plate theory. Furthermore, composite designs are analyzed to determine if they meet appropriate design criteria, such as a failure or deflection criteria.

See a class you wish to take? Visit the site for upcoming course schedules.

Additional learning opportunities

Prof. Hansen can provide trainings for students and industry to become certified in 3D printing. UMass Lowell is an approved certification site. Read more at the Stratasys press release.

Prof. Hansen and graduate student Catie Barry taught a class of 15+ female high school students about how to think about safer solvents in the products we use. More information on the summer camps can be found here.

innovative engineering instruction

Prof. Hansen uses instruction approaches that include team competitions, service-learning, wikipedia projects, industry/site tours, and more.

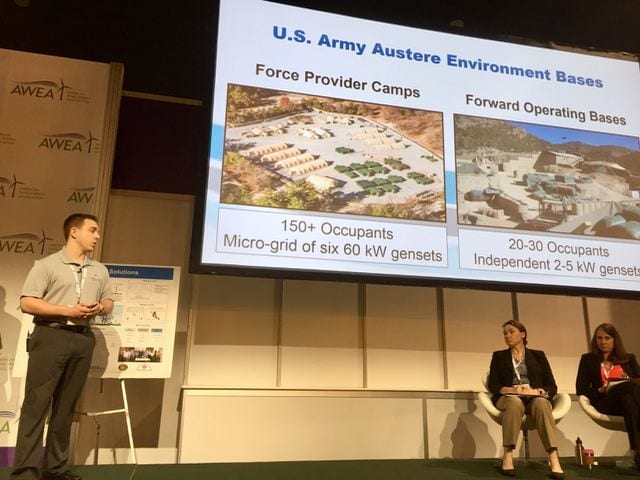

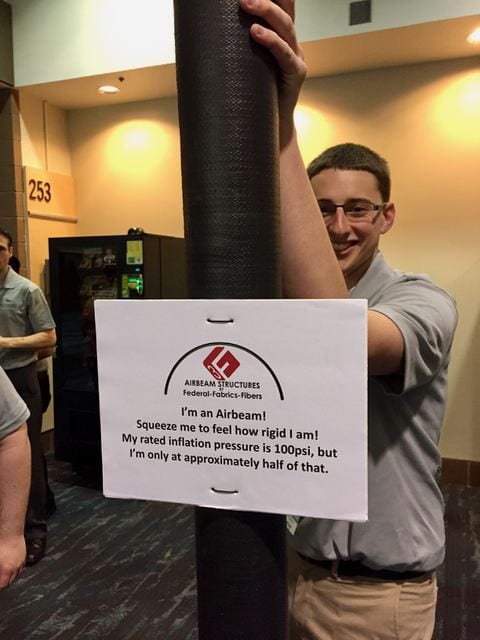

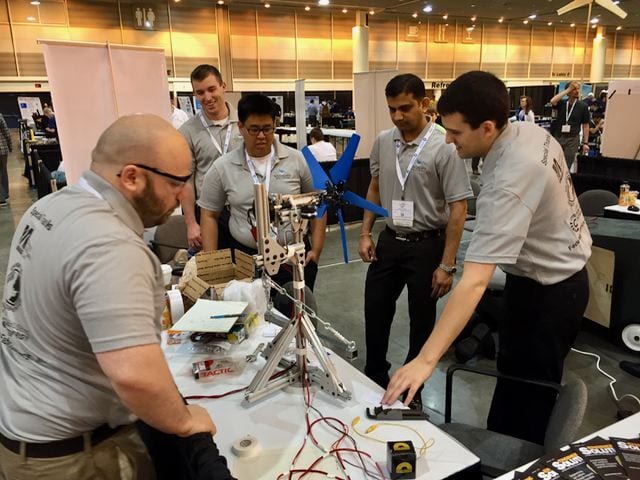

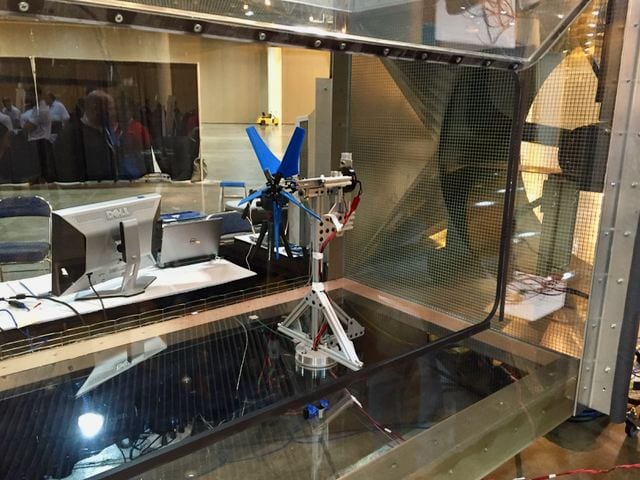

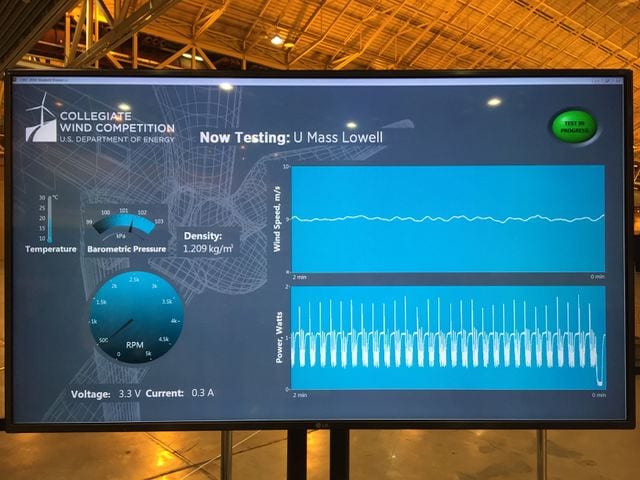

Prof. Hansen has co-advised multiple interdisciplinary senior design teams who have competed in national competitions. Students have competed in the 2014 Collegiate Wind Competition (CWC) with a 3rd place finish nationally, and in the 2016 Collegiate Wind Competition, where they placed 2nd place nationally! The Department of Energy funded the CWC events and they were hosted at the American Wind Energy Association (AWEA) national meetings.

The following gallery contains photos from the UML Team WindHawk’s time at the 2016 CWC, held at the AWEA meeting in New Orleans, LA.

Service-Learning is an service-oriented educational experience in which students meet community needs and reflect on the service activity to deepen their course understanding, gain a broader appreciation of their discipline, and an enhanced sense of civic responsibility.

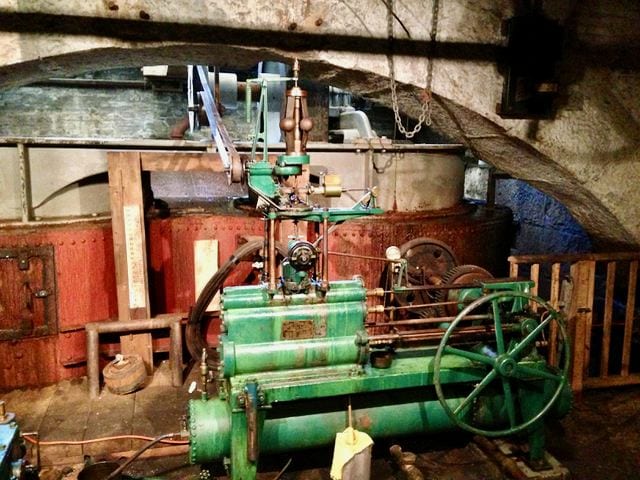

In Materials Science for Engineers, we have worked with the Tsongas Industry History Center (TIHC) and the Lowell National Historical Park to investigate the use of materials in the historic textile mills. This information was summarized for use by TIHC staff and National Park Service rangers in public tours & education programs.

In the Strength of Materials course, we worked with the Lowell Transitional Living Center (LTLC), which provides services aimed at ending homelessness. During the bitter winter cold, additional beds are provided by cots — but these would sometimes break. Students used their course knowledge to analyze the failure and to propose a solution. The best solutions were implemented at LTLC for ~$10 per cot. The cots no longer broke, saving the center hundreds of dollars per year.

The story was covered in this UML news article.

The Honors section of Materials Science for Engineers applied their course skills on information resources and materials science to enhance so-called ‘stub’ articles on Wikipedia. In less than 1 month, the revised articles were read over 41,000 times!

Some of the popular articles are:

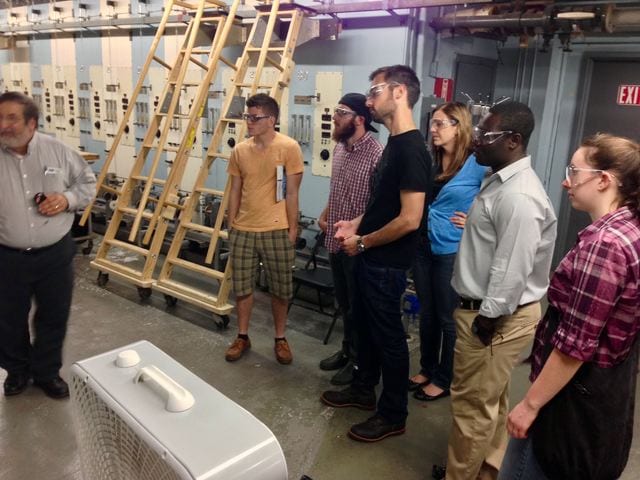

Coursework is often enhanced by visibly seeing the course content implemented in the real world. The Processing of Composites (MECH 5970) course has toured multiple sites in the Greater Boston Area. Some of these site tours are listed below.

Students from the Processing of Composites course toured AvCarb Material Solutions. The tour included carbon fiber production, yarn twisting and stretch-breaking, and weaving processes.

Students from the Processing of Composites course toured Specialty Materials Inc. The tour included the only boron fiber manufacturing line in the world, as well as pre-pregging, hybrid fibers, carbon fiber spinning, and boron-magnesium nanoparticle production.

Students from 22.597 "Processing of Composites" visited Plasan U.S. Defense Composite Structures in Woburn MA. Students saw the largest pultrusion manufacturing set-up in the world, in addition to filament winding.

Prof. Hansen uses multiple technologies to assist with learning both inside and outside the classroom. Examples include video lecture recordings (Echo360), Blackboard course sites, Brainshark pre-lecture videos, clickers, online advising, and more.