The Hansen research group has four primary research thrusts.

We learn about new materials and hybrid printing methods that push the boundaries of 3D printed part performance.

We investigate new techniques that enable multi-functional composites and automated composites manufacturing.

We re-formulate products to maintain performance while removing chemicals harmful to health and the environment.

We aim to understand engineering education so that students are motivated and able to learn cutting-edge science & technology.

The rapidly advancing field of 3D printing continues to have substantial fundamental scientific and technological challenges to be addressed. Novel materials, new formats of input materials, multi-material printing, and pushing the boundaries of 3D printing machines and equipment are some topics we study.

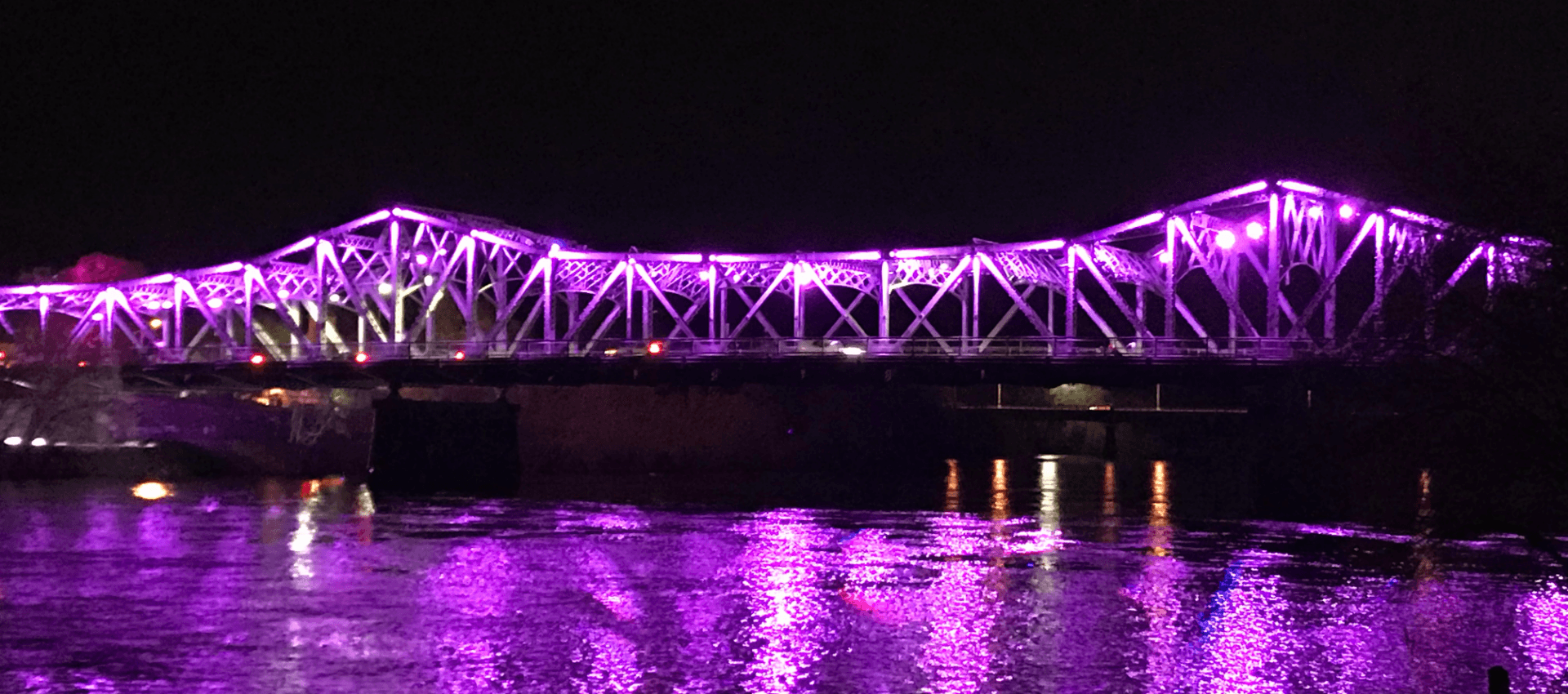

This NSF I/UCRC (Industry/University Cooperative Research Center) is the sole center of its type to focus on 3D printing. The center's industry and government members direct the research priorities and tightly interact with the research teams. UMass Lowell is joined by UCONN and Georgia Tech as the three academic sites. Learn more at SHAP3D's website or LinkedIn page.

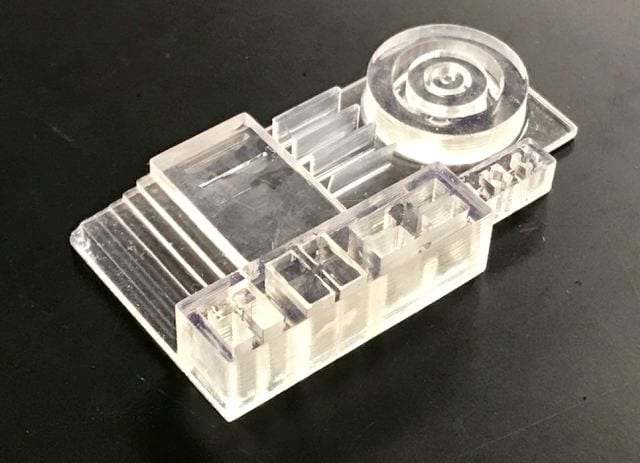

Stereolithography (SLA) photocures a liquid resin to obtain a solid part where exposed to light. Our team is developing novel formulations that expand the material properties envelope to create high performance structures.

UMass Lowell has the largest academic collection of polymer processing equipment in the United States. Using these considerable resources and in collaborations with the renowned Plastics Engineering department, we have extruded custom filaments from neat or compounded polymers, at diameters ranging from 100 µm to 3+ millimeters, and in lengths from less than 1 meter to in excess of 1 kilometer!

Composite materials are increasingly valued for their exceptional performance in engineering applications. Our group investigates the fabrication, processing, and manufacturing of these advanced materials.

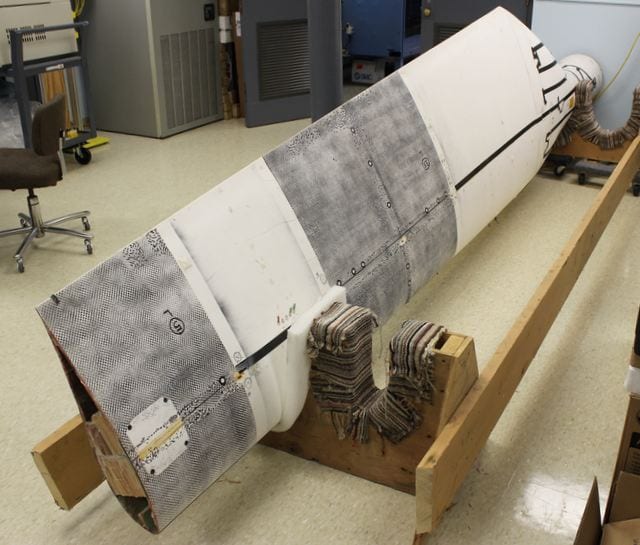

Automated Fiber Placement (AFP) is an automated process to lay-up fiber-reinforced composites using a gantry- or robotic arm-style controlled motion. We have teamed with aerospace partners to investigate the incorporation of multi-functional components into AFP manufacturing. Currently we are working with NASA to determine the effects of manufacturing and environmental parameters on the performance of space structures fabricated by AFP.

Utility-scale wind energy capture relies on increasingly lengthy and massive turbine blades. The scale of these blades present challenges of how to increase their lifetime, performance, and durability. We collaborate with the WindSTAR I/UCRC and their industrial members to work on fundamental research with direct real-world relevance.

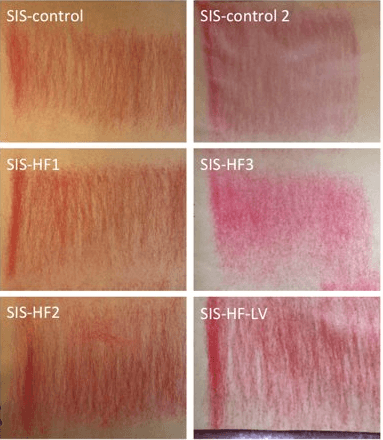

Composite materials offer superior structural performance, but also offer the opportunity to incorporate secondary functionalities during fabrication. We investigate how to manufacture composites with self-healing, thermal regulation, structural health monitoring, and other functionalities while retaining high quality structural performance.

Materials science increasingly focuses on sustainability from the perspective of both human health as well as the environment. Our group investigates

Some consumer and industrial products contain chemicals that are Hazardous Air Pollutants (HAPs), carcinogenic or reproductive hazards, cause smog (i.e., ozone at ground level), or are bioaccumulative or persistent in the environment. Using Hansen Solubility Parameters (HSPs) -- no relation to Prof. Hansen! -- we can identify alternative chemicals that provide similar or improved performance while reducing or eliminating these hazards. We have worked with industry to reformulate contact adhesive resins, as well as with reformulation of paint strippers.

Hobbyists love to 3D print their latest creative pieces, often in a printer alongside their desktop computer. Occupational health researchers are asking whether this poses any health issues. We bring an engineering perspective with significant additive manufacturing expertise to these discussions.

The rapidly advancing field of 3D printing continues to have substantial fundamental scientific and technological challenges to be addressed.

Student motivation is a key ingredient to the learning process. We have studied the use of hobbyist CNC machines and blocks with 1-axis of motion in project-based or hands-on courses, and their effect on student motivation

Prof. Hansen also integrates innovative pedagogies into his coursework. Visit the teaching page for more information.

For a full publication list (including earlier publications), please visit Prof. Hansen’s ORCID or Google Scholar profile.

2020

2019

J. Morris, C.J. Hansen, A.V. Amirkhizi. “Improved Approximation of Transverse and Shear Stiffness for High Volume Fraction Uniaxial Composites.” Mechanics of Materials, 129, pp. 230-235 (2019). DOI: 10.1016/j.mechmat.2018.11.014.

D.J. Willis, C. Niezrecki, D. Kuchma, E. Hines, S. Arwade, R.J. Barthelmie, M. DiPaola, P.J. Drane, C.J. Hansen, M. Inalpolat, J.H. Mack, A.T. Myers, M. Rotea. “Wind Energy Research: State-of-the-Art and Future Research Directions.” Renewable Energy. 125, pp. 133-154 (2018). DOI: 10.1016/j.renene.2018.02.049.

R.H. Awad, S.A. Habash, C.J. Hansen. “Chapter 2: 3D Printing Methods.” 3D Printing Applications in Cardiovascular Medicine, edited S. Dunham. (2018). ISBN-13: 978-0-12- 803917-5.

S. Dev, P.N. Shah, Y. Zhang, D. Ryan, C.J. Hansen, Y. Lee. “Synthesis and Mechanical Properties of Flame Retardant Vinyl Ester Resin.” Polymer, 133, pp. 20-29 (2017). DOI: 10.1016/j.polymer.2017.11.017.

C. Barry, G. Morose, K. Begin, M. Atwater, C.J. Hansen. “The Identification and Screening of Lower Toxicity Solvents for Contact Adhesives.” International Journal of Adhesion and Adhesives. 78, pp. 174-181 (2017). DOI: 10.1016/j.ijadhadh.2017.06.022.

P.N. Shah, S. Dev, Y. Lee, C.J. Hansen. “Processing and Mechanical Properties of Bio- Based Vinyl Ester Resin-Based Composites.” Journal of Applied Polymer Science. 134, no. 13 (2017). DOI: /10.1002/app.44642.

L. Dangora, C.J. Hansen, C. Mitchell, J. Sherwood, J. Parker. “Challenges Associated with Shear Characterization of a Cross-ply Thermoplastic Lamina using Picture Frame Tests. Composites Part A: Applied Science and Manufacturing, 78, pp. 181-190 (2015). DOI: 10.1016/j.compositesa.2015.08.015.

C.J. Hansen. “Chapter 5: Microvascular-based self-healing materials.” Recent advances in smart self-healing polymers and composites, edited by G. Li, H. Meng, and G. Jones. (2015). ISBN-13: 978-1782422921.

C.J. Hansen. “Chapter 8: Microvascular transport.” Multifunctional Composites, edited by E. Barbero. (2015). ISBN-13: 978-1516804528.