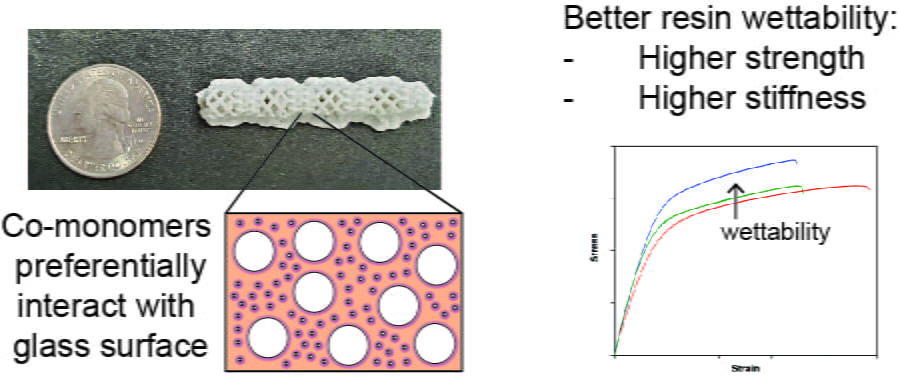

Vat photopolymerization of highly filled polymer composites

We fabricate highly filled (50-70 vol.%), high resolution composite structures via vat photopolymerization. We have demonstrated that mechanics of these composites can be tailored through the reinforcement-polymer interface.

Publications:

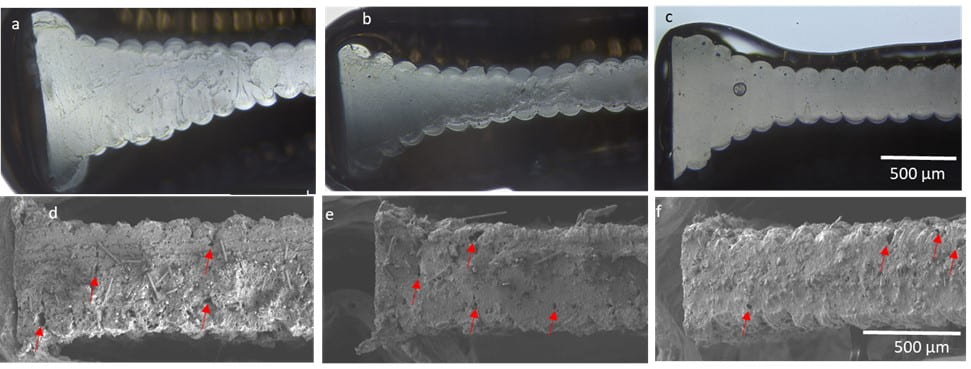

Material extrusion additive manufacturing of semi-crystalline polymers

We investigate what leads to printability in semi-crystalline polymers by comparing a hot melt adhesive and a Nylon. The hot melt adhesive is capable of bulk, or better than bulk, properties when additively manufactured, so we have explored reasons why and have also investigated the effect of reinforcement on printed structure performance.

Publications:

Adaptive Fused Filament Fabrication

We explore how to enable on-line property prediction in desktop scale material extrusion (fused filament fabrication, FFF).

Publications:

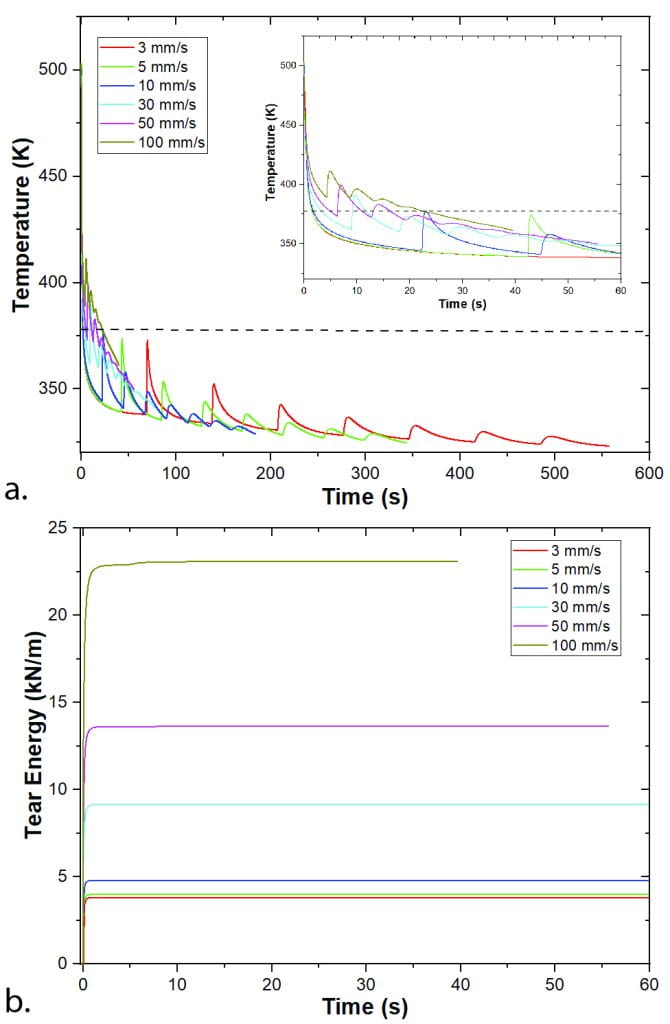

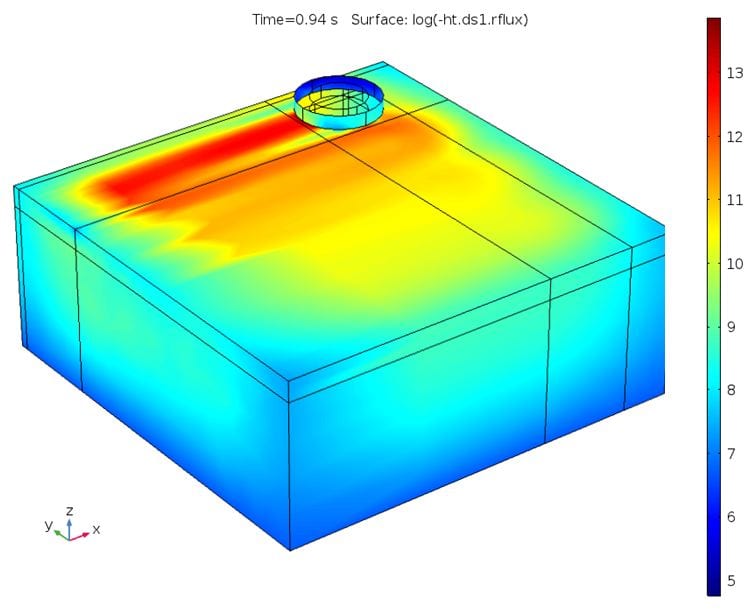

Finite element modeling of material extrusion additive manufacturing

We use FEA to model thermal profiles in MatEx structures, from the benchtop (fused filament fabrication, FFF) to room (big area additive manufacturing, BAAM) scales. This research helps us answer questions such as: 1. What print parameters are important to part performance and why? 2. What makes a material printable? 3. What is the role of printer/print scale on dominating physics? 4. What is the “best” toolpath for a given structure?

Publications:

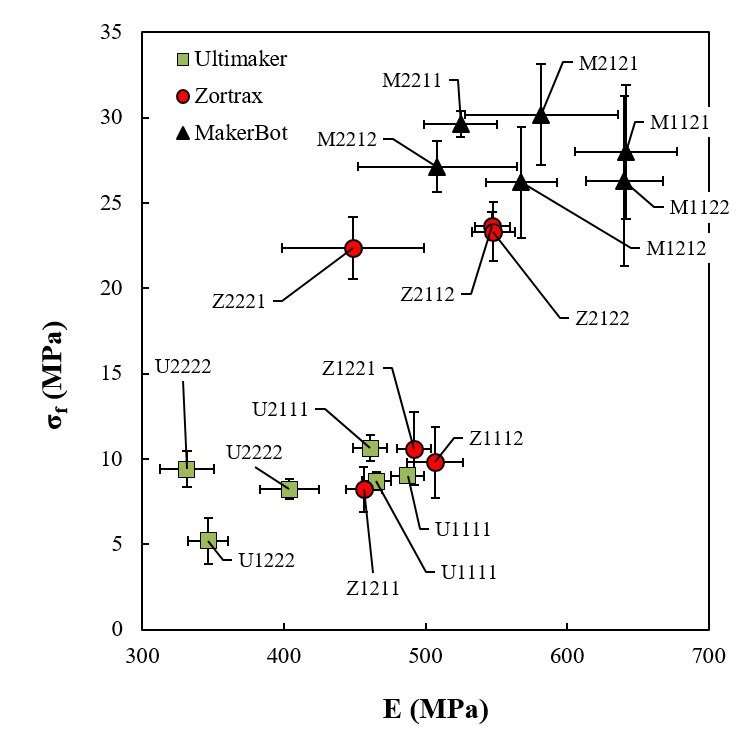

Materials informatics approaches to AM

Processing–structure–property relationships in material extrusion additive manufacturing are complex, nonlinear, and poorly understood. We designed an informatics workflow for the collection of high-pedigree data from each stage of the FFF printing process. In conjunction with a design of experiments, we applied the workflow to investigate the influences of processing parameters on weld strength across three commercially available FFF printers. Environmental, material, and print conditions that may impact performance were monitored to ensure that relevant data were collected in a consistent manner.

Data: Complete raw experimental data, analyzed data, metadata, and failure surface images are available through download at the NIST Dspace repositories.

Publication:

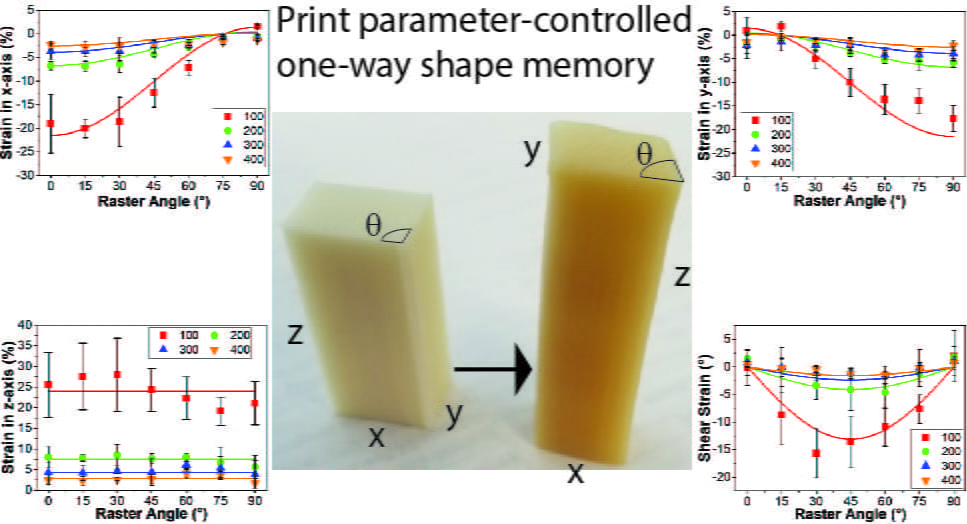

Residual stress-based shape memory

We have observed and explored the source of irreversible thermal strain of FFF structures upon annealing above the glass transition temperature. Based on a micromechanical framework, we can predict irreversible thermal strain in x, y, and z, as well as shear transformation of printed structures.

Publications:

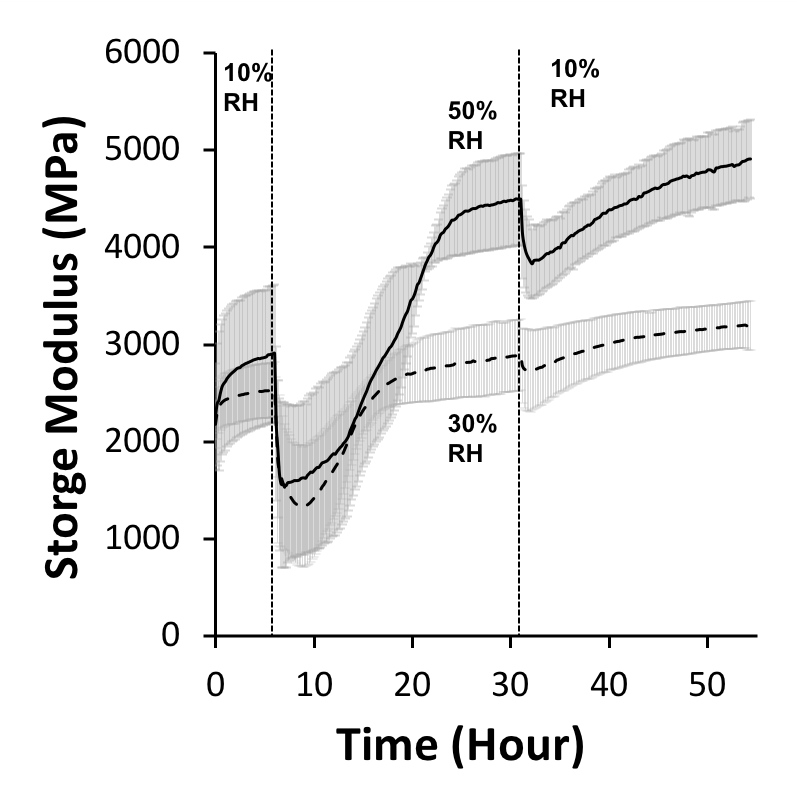

Humidity tempering of polyelectrolyte complexes

Water plays an important role in the structure and properties of polyelectrolyte-based materials. We have explored as a novel approach to tailoring the structure and mechanical properties of polyelectrolyte-based materials under mild conditions that are well-suited to biomaterials and controlled release. After exposure to higher humidities (humidity tempering), water from the humid air plasticizes the PEC, increasing mobility and facilitating chain reorganization, which results in a structure with more intrinsic electrostatic bonds (cross-links) and higher moduli. Humidity tempering can achieve a 35% increase in PEC stiffness during room temperature processing with water as the only solvent.

Publications:

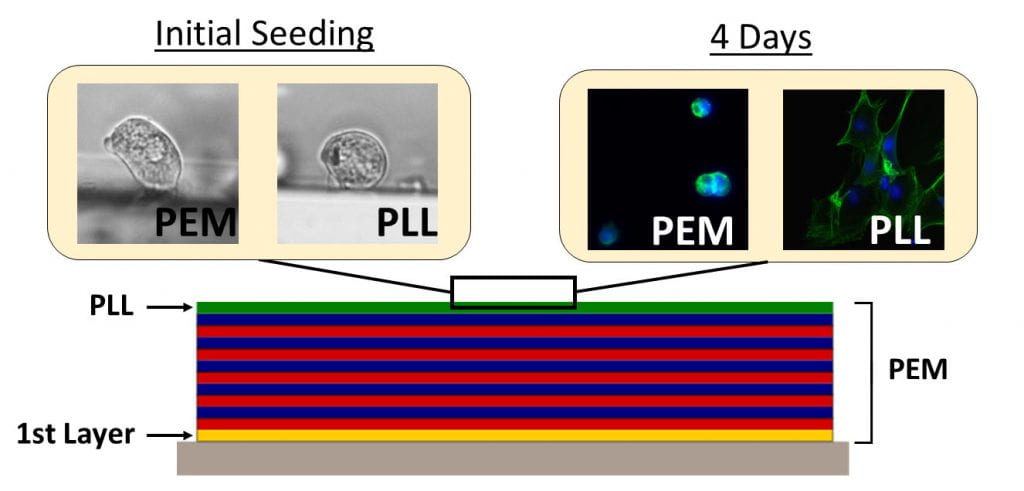

Assembly-driven control on polyelectrolyte multilayers

In many applications of PEMs, a base polycation layer is adsorbed to promote adhesion of the PEM to the substrate. We have investigated the effect of the first polyelectrolyte adsorbed in a PEM by assembling PEMs with first layer polycations of different chemistries and molecular weights. First layer choice affects the total mass accumulation of the PEM as well as the stoichiometry of the PEM. These findings indicate that the structure of a PEM is fundamentally different depending on first layer chemistry and molecular weight. PEM topography is also affected by first layer choice. We have subsequently harnessed this knowledge to create model substrates for probing individual affects of substrate properties on cell culture.

Publications:

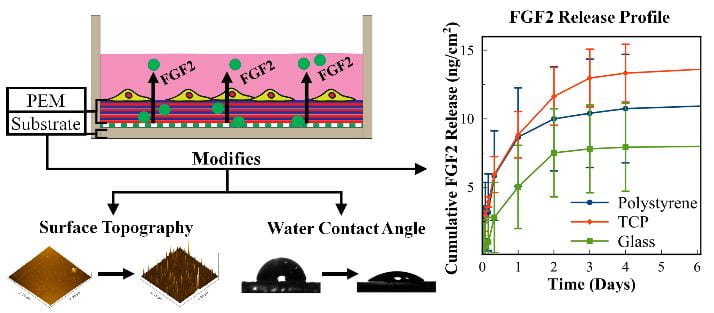

Growth factor release from polyelectrolyte multilayers

GFs act as biochemical cues for cells and, as such, are powerful tools for modulating tissue regeneration, wound healing and cancer treatment. However, their application in biomedicine is challenging for a number of reasons, including cost, stability, and myriad potential negative outcomes when GF amount and release location are not optimized. We investigate the role of assembly conditions on PEM surface properties and GF/drug release. Our overarching goal is to develop fully tailorable PEMs so that we can study the independent, competing, and synergistic effects of physical, chemical, and biochemical cues on cell function independently, then harness these systems for cell manufacturing and tissue engineering.

Publications: