Research in the Sobkowicz group is focused on the convergence of polymer science and engineering and sustainability. We are interested in manufacturing and engineering approaches to improve the environmental profile of plastics, while seeking deeper understanding of structure-processing-property relationships in the systems we investigate.

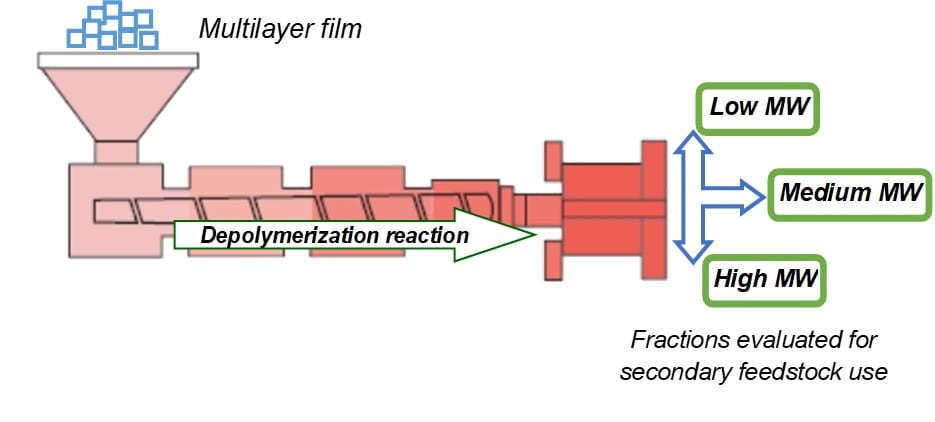

We are studying high speed reactive extrusion for hybrid chemical-mechanical recycling of multi-component polymer flexible films. We aim to produce new packaging and other materials from multilayer plastic film through partial depolymerization and homogenization. Most existing recycling schemes for multi-polymer blends result in downcycling, severely limiting industrial viability due to lowered value. In our work, we create new chemical and material streams with added value as new flexible film (high molecular weight (MW)), compatibilizer tie layers or adhesives (medium MW), and polymer additives or lubricant oils (Low MW).

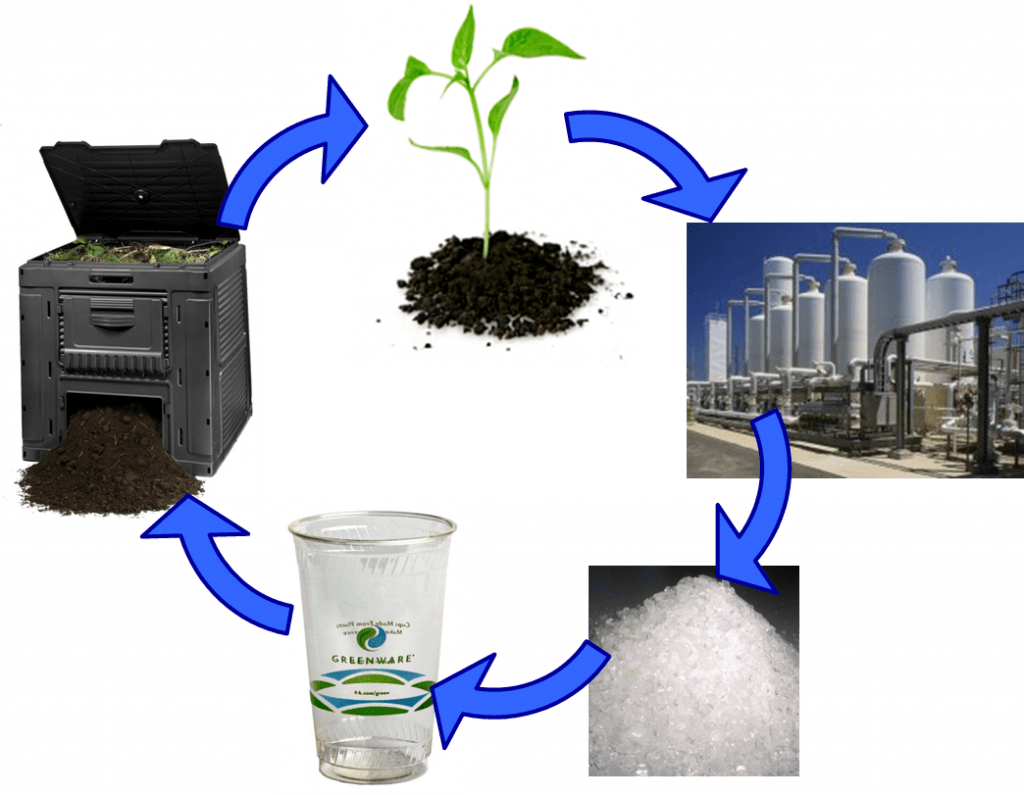

We are syntheizing biodegradable, biobased polymers with the aim of producing novel compounds for agricultural applications. We are studying the bimodal release of chemicals from these polymers through simultaneous control over degradation and diffusion. These coatings could provide an enviromentally friendly solution to over-fertilization and migration of pesticides and herbicides. The use of controlled release schemes can prevent water contamination from runoff, while approaching plant health in a more tailored way.

In this project, we are working with thermally conductive composites to produce tubing to be used in heat exchange devices. State of the art thermal regulation garments use conventional plastic tubing that impedes thermal transport into the flowing fluid. By reducing the thermal resistance through the tube, we can improve the efficiency of the devices. However, these thermally conductive composites are also challenging to process due to their high filler content. Our research seeks connections between the processing, structure, and performance in this tubing.